Solar Power

Providing Quality Repairs with

Exceptional Customer Service Since 1913

For more than 100 years, TEAMSESCO has set the standard in the electronic repair industry. Creating schematics and accumulating repair data for thousands of brands on more than 150,000 unique part numbers has given us a unique advantage within the industry. With a vast library of schematics and diagrams of various renewable components, we continue to set ourselves apart from the competition.

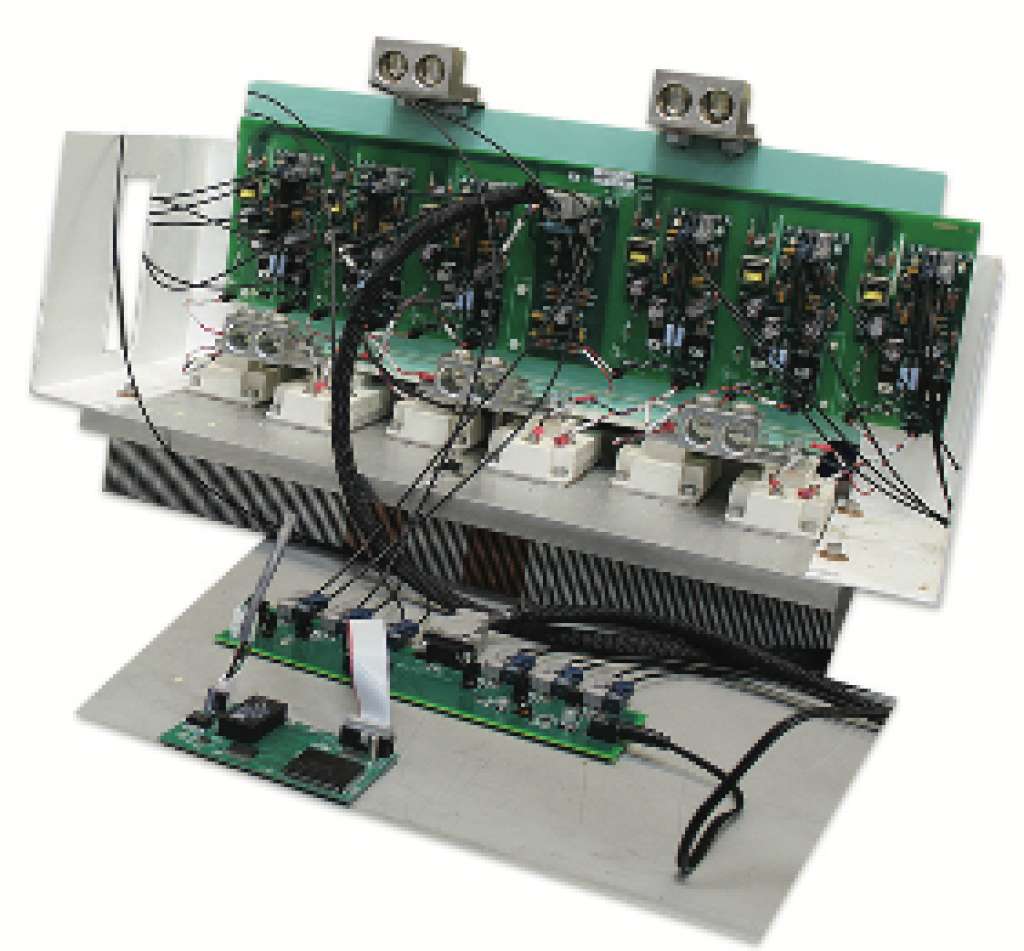

Today, more renewable companies rely on TEAMSESCO for their electronic repair solutions than ever before! We continue to expand our capabilities through our engineering team and grow our business by offering the very best.... the best technicians, the best test equipment and the best procedures. Our leadership role in Renewable electronic repair has been achieved by partnering with our customers, identifying their current and future needs, staying on the forefront of technology and utilizing state of the art test equipment, such as our industry exclusive closed loop, hydraulic load center.

TEAMSESCO knows the only way to ensure the quality of any repair is to fully understand the units internal workings, to have the ability to run the unit at full rated load capacity and to test and control its communication functions. Our engineering team spends the time needed to reverse engineer every renewable component we repair, to create schematics, to identify high failure rate components and to find and resolve OEM design flaws. Most importantly, we create written repair and load test procedures. When possible, we run and test all repaired units under full-rated load capacity. Our custom-built load center is fully adjustable direct from the technican's workbenches where it can run indefinitely or for any variable amount of time to be certain that the unit will sustain its full-rated load capacity!

Some of the brands we service:

- ABB

- Advanced Energy

- General Electric

- Kaco

- Power Electronics

- Schneider Electric

- Semikron

- SMA

- Sunpower